The Challenge: Prose and Manual Processes

Business rules are the invisible framework of your company. They determine how decisions are made, what criteria must be met, and how workflows are structured. However, today these rules are often documented in policies, guidelines, and best practices in pure “prose.”

The problem?

– When handling customer inquiries, orders, or complaints, employees must sift through documentation to find the relevant rules.

– This is not only time-consuming but also prone to errors.

Perhaps you have already considered using generative AI (GenAI) for decision-making. However, in practice, this often reaches its limits:

– The rules are vaguely formulated, sometimes contradictory.

– The AI’s decisions are not always transparent.

– Can you really trust it?

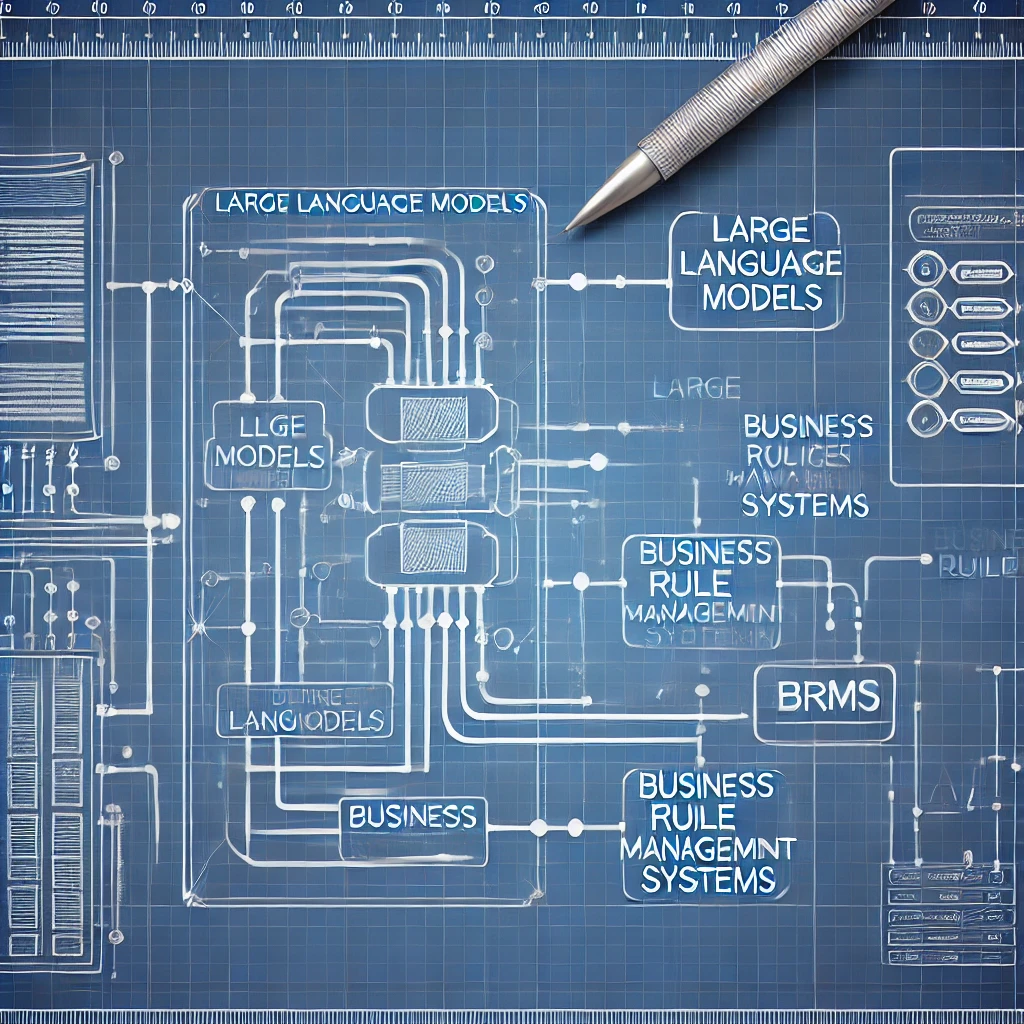

My Proposal: LLM + BRMS – A Rarely Implemented Combination

Business Rules Management Systems (BRMS) offer a proven solution:

– Rules are stored in a machine-readable format and automatically validated.

– The challenge has been the labor-intensive manual transfer of rules into a BRMS.

– The good news? Large Language Models (LLMs) can drastically simplify this process.

Two-Stage Process for AI-Supported Business Rule Processing

1. Preprocessing (Rule Extraction & Standardization)

– Your documents—contracts, policies, and best practices—are analyzed by an LLM.

– The AI extracts relevant rules and converts them into a standardized, machine-readable format.

– A manual review by an AI administrator ensures that the rules are correct and free of contradictions.

2. Processing (Automated Decision-Making)

– Customer inquiries (claims, orders, requests) are processed by a traditional AI.

– The AI extracts relevant data and forwards it to your workflow system.

– Decisions are based on the rules stored in the BRMS, which have been reviewed by human experts.

Why This Approach Works

1. The Best of Both Worlds: LLM + Traditional AI

– LLMs handle the tedious task of extracting rules from documents.

– Traditional AI processes inquiries and structures input data.

2. Human Oversight for Security and Precision

– Rules are not blindly adopted but validated by experts.

– Errors and unclear formulations can be identified and corrected early.

3. Transparency and Traceability

– No black-box decisions: all rules are explicitly stored and traceable.

– No risk of “hallucinations” or bias from a generative AI.

– You always have control and can review and adjust decisions.

Why You Should Consider This Now

The combination of LLMs and BRMS is a promising approach to making business rule management more efficient and transparent. You can:

– Save time.

– Reduce errors.

– Establish an AI-supported yet human-controlled decision management system.

Since this approach has been rarely implemented so far, it is worth exploring its potential for your company in more detail.

Sources:

[1]: Original diagram for AI-supported business rule processing, created by the author.